Quality Assurance vs Quality Control: What’s the Real Difference?

In the current competitive marketplace, businesses are faced with tremendous pressure to deliver products and services that not only meet but exceed customer expectations. In this context, the terms quality assurance (QA) and quality control (QC) are frequently mentioned and are sometimes used interchangeably. At first glance, they may seem to be for the same purpose, to make sure of quality. However, in reality they play very different roles in an organization.

But wait, first we have to define quality. Quality is the ability of a product or service to meet specifications and satisfy customer needs. Although both QA and QC are aiming for quality, they approach it differently. QA is about creating a process to avoid errors. QC is the error finding and rectifying process. The difference is important for businesses trying to minimize the errors and expense involved in developing customer relationships.

What is Quality Assurance?

Quality assurance is a proactive and preventative strategy. It focuses on processes that ensure that all production, or service delivery processes meet high standards. Instead of waiting for errors to occur, QA strives to prevent them through structured planning, documentation and training.

The meaning of QA is in the design and implementation of systems that make errors less probable in the first place. For example, in a software development company, QA makes sure that the developers adhere to coding standards, perform reviews at each stage of development, and implement testing mechanisms at each stage. Similarly, in healthcare, QA processes ensure that treatments are done in accordance with regulatory standards and patient safety guidelines even prior to treatment. In short QA is about establishing confidence that everything is being done correctly right from the start.

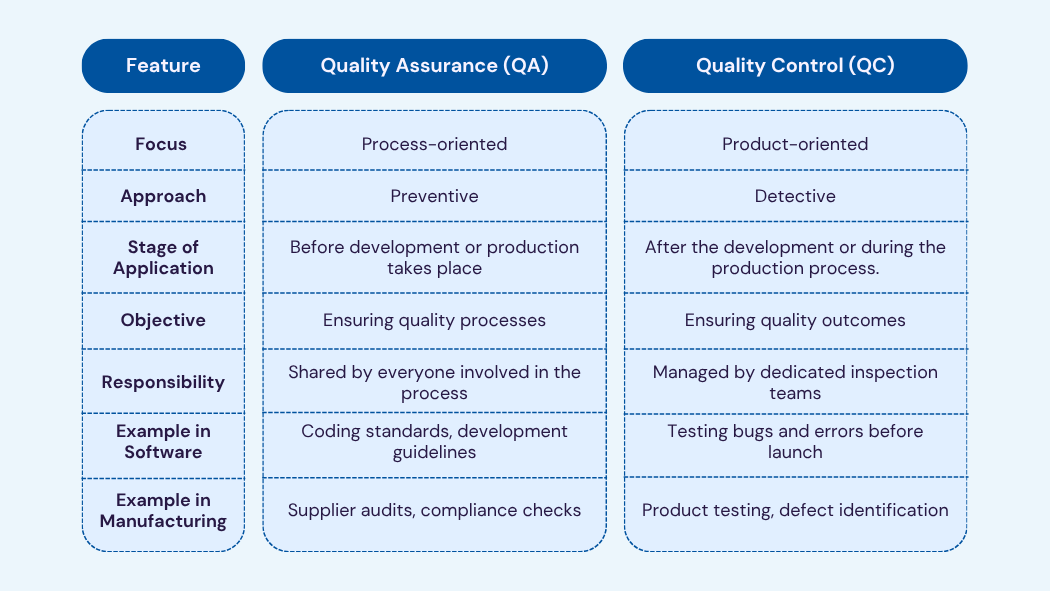

Quality Assurance vs Quality Control: Understanding the Core Difference

The simplest way of remembering the difference between quality control and quality assurance is this:

- QA is a process: getting it right the first time.

- QC is product focused: checking if the product was built correctly.

In other words: QA is used to prevent defects; QC is used to detect them.

Comparative Table: QA vs QC

The above comparison makes it clear why quality assurance vs quality control is not a choice of one over the other. Instead, businesses should view them as mutually supportive tools, which work hand-in-hand to achieve excellence.

What is Quality Control?

While QA works on being proactive, quality control is reactive. QC is carried out after production or delivery of services and is aimed at finding defects or inconsistencies in the final product. This entails stringent testing, inspection, and verification to ensure products meet specified requirements.

The definition of QC is focused on error detection rather than error prevention. For instance, in manufacturing, QC testing is performed on batches of a product to ensure that they are durable and safe. In software, QC is used in the final stage of testing where bugs are found and fixed before it’s released. Although QC is a later part of the process, it is equally important because it ensures that only error-free products are distributed to the customer.

Common Misconceptions Around Quality Assurance vs Quality Control

Despite the obvious differences, there is still confusion. Many organizations make the common error of thinking:

- QA is not compulsory while QC is obligatory.

- Quality control alone can ensure quality but without guarantee.

- There is no overlap between QA and QC as they are two distinct departments.

In fact, quality assurance vs quality control is not a question of ‘which is better’, but an understanding that both are necessary to ensure consistent, reliable and safe results.

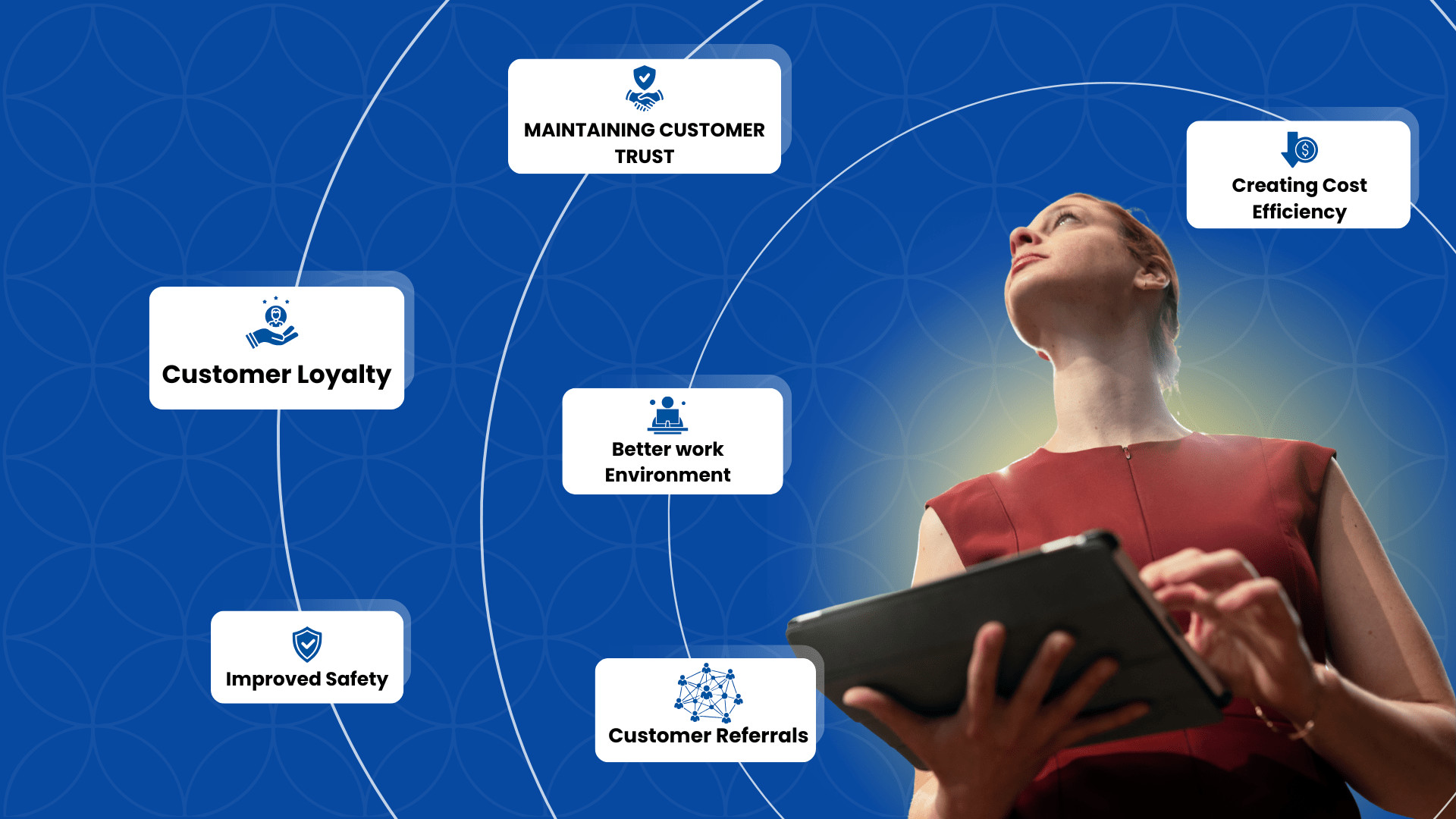

Why Businesses Need Both QA and QC

Companies that use QC alone find problems too late, when the cost of fixing them is at its peak. On the other hand, organizations that rely solely on QA may not be able to identify unexpected issues in the final product. That is why, QA and QC are a compatible combination that minimizes risk, rework and improves quality at all stages.

When used simultaneously, QA and QC help organizations minimize operations costs, maintain regulatory compliance programs, decrease defect rates and achieve enhanced customer satisfaction. That’s why whether it is IT, retail, pharmacy or FMCG industry everyone has some kind of QA/QC process in place.

Real-World Applications of QA and QC

QA and QC are used differently in industries but the principle is the same. In the construction industry, QA is the process of developing detailed safety and compliance procedures, and QC is the process of frequent site inspections to determine if standards are being met. In the pharmaceuticals industry, QA can be used to ensure that the production process follows strict regulations, while QC can be used to verify the chemical composition and safety of each batch of drugs.

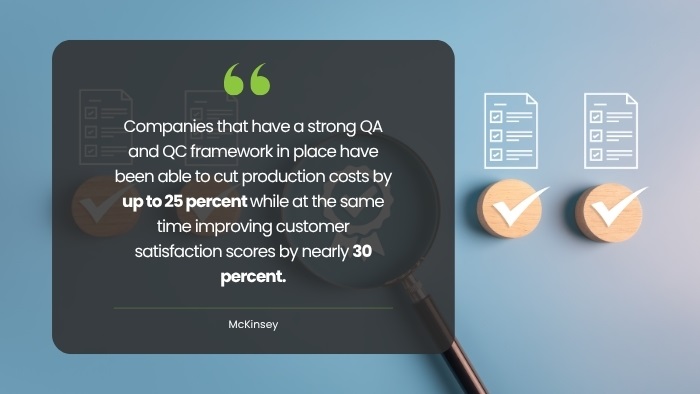

According to a McKinsey report, companies that have a strong QA and QC framework in place have been able to cut production costs by up to 25% while at the same time improving customer satisfaction scores by nearly 30 percent. These numbers give emphasis to the fact that integrating QA and QC is not a matter of compliance – it’s a matter of efficiency and profitability.

The Growing Role of Quality Assurance Services

In the modern globalized business environment, many companies are resorting to specialized QA services providers to fortify their systems. These providers assist in formulating processes to meet international standards, performing compliance checks and implementing good QA/QC practices in a number of industries.

For example, in technology-driven industries such as software development, QA services are used to ensure that platforms – whether customer support software, 360 feedback systems or enterprise applications – perform consistently. In traditional industries such as retail and manufacturing, QA services help integrate global compliance with the supply chain; QC ensures that the products shipped to customers are defect free.

Conclusion: Why QA and QC Are Stronger Together

So, what is QA and what is QC? In other words, QA is a preventative process, whereas QC is a detection process. QA is the proactive buffer that fortifies processes, and QC is the detective’s eye that examines results. When they work together, they form a comprehensive approach that guarantees high quality of both processes and products.

The debate is no longer quality assurance vs quality control but how the two can be used together to achieve operational excellence. When one single issue is enough to ruin a company’s reputation or create millions in rework, making an investment into QA and QC is no longer a “nice-to-have,” but rather becomes an imperative. Businesses building with a mix of both methods are more resilient, more reliable and deliver compounding value for customers.

The actual difference is not between QA or QC but knowing that together, they are the foundation for long-term success.

Author